Your shopping basket

Made with Love

Made with Love

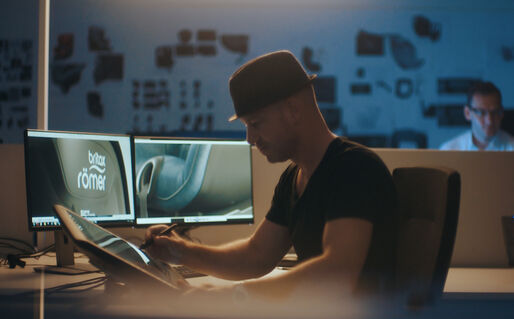

From the initial idea to a safe child car seat

It takes two to three years to develop a new Britax Römer child car seat. All departments involved, from the initial idea to testing and production, are housed under one roof. Because of this all teams can work together to achieve our common goal of producing the safest car seats.

Made with a vision

In the beginning, the initial idea is combined with German engineering. Product development is a continuous process involving a team of product managers, product designers and engineers. Our internal product design, testing and simulation teams work closely together to create the first CAD (Computer-Aided Design) models. The team evaluates the models, crash tests are carried out and the model is refined. Then the process starts again until the child car seat meets our strict requirements.

Made with care

According to this principle, we create and design products which are stylish, reflecting the current trends and colours.

For us, safety and design go hand in hand. That’s why we take great care to ensure that the materials used contain as few harmful substances as possible and are of the highest quality.

The result is a product that not only guarantees safety, but is also ergonomic and well designed.

Made to protect

During the development process a child seat undergoes various tests over and over again. We use Computer Aided Engineering (CAE) to reconstruct detailed crash simulations virtually. This gives us detailed insights into the effects of an accident.

But even when the seat is in serial production, testing does not end. We test seats from production on our crash test facilities at regular intervals and test the harness and other safety components as well.

Made with knowledge

The production of our seats is carried out manually. That way we can ensure that every screw fits perfectly and that a safe product is created.

Working with our suppliers, we request the shortest possible transportation routes. This creates synergies and improves collaboration during product development. Last but not least, we are setting a strong standard for sustainability and improved CO2 balance through short transportation routes and reduced packaging materials.